What is fluoropolymer ?

Fluoropolymer is thermoplastic polymers composed of elemental fluorine and carbon chains, which are abundant in fluorite.

Even if it is said that it is a fluoropolymer, there are various types as showing as below.

| Property | Unit | Test Method | PTFE | PFA | FEP | ETFE | |||

|---|---|---|---|---|---|---|---|---|---|

| JIS | ISO | ASTM | |||||||

| Melting Point | °C | K 6935 | 12086 | D 4591 | 327 | 310 | 260 | 270 | |

| Tensile Strength | MPa | K 7162 | 527 | D 638 | 20-35 | 25-35 | 20-30 | 38-42 | |

| Elongation | % | K 7162 | 527 | D 638 | 200-400 | 300-350 | 250-330 | 300-400 | |

| Dynamic Friction Coefficient | [0.69MPa, 3m/min] | K 6935 | D 1894 | 0.1 | 0.2 | 0.3 | 0.4 | ||

| Thermal Conductivity | W/m·K | A 1412 | 8302 | C 177 | 0.23 | 0.19 | 0.2 | 0.24 | |

| Max Operating Temp | °C | K 7226 | 2578 | 260 | 260 | 200 | 150 | ||

| Water Absorption | %[24hr] | K 7209 | 62 | D 570 | 0.01 | 0.01 | 0.01 | 0.03 | |

| Flame Retardant | [3.2 mm thick] | K 7140 | 1210 | UL-94 | V-0 | V-0 | V-0 | V-0 | |

| Chemical Resistance | Acid | D 543 | |||||||

| Alkari | |||||||||

| Organic Solvent | |||||||||

: Not affected by most chemicals and solvents even under harsh conditions.

: Necessary to use some chemicals and solvents with care under certain conditions.

Ref : Japan Fluoropolymers Industry Association "List of fluoropolymer characteristics"

Where Fluoropolymer coating are used ?

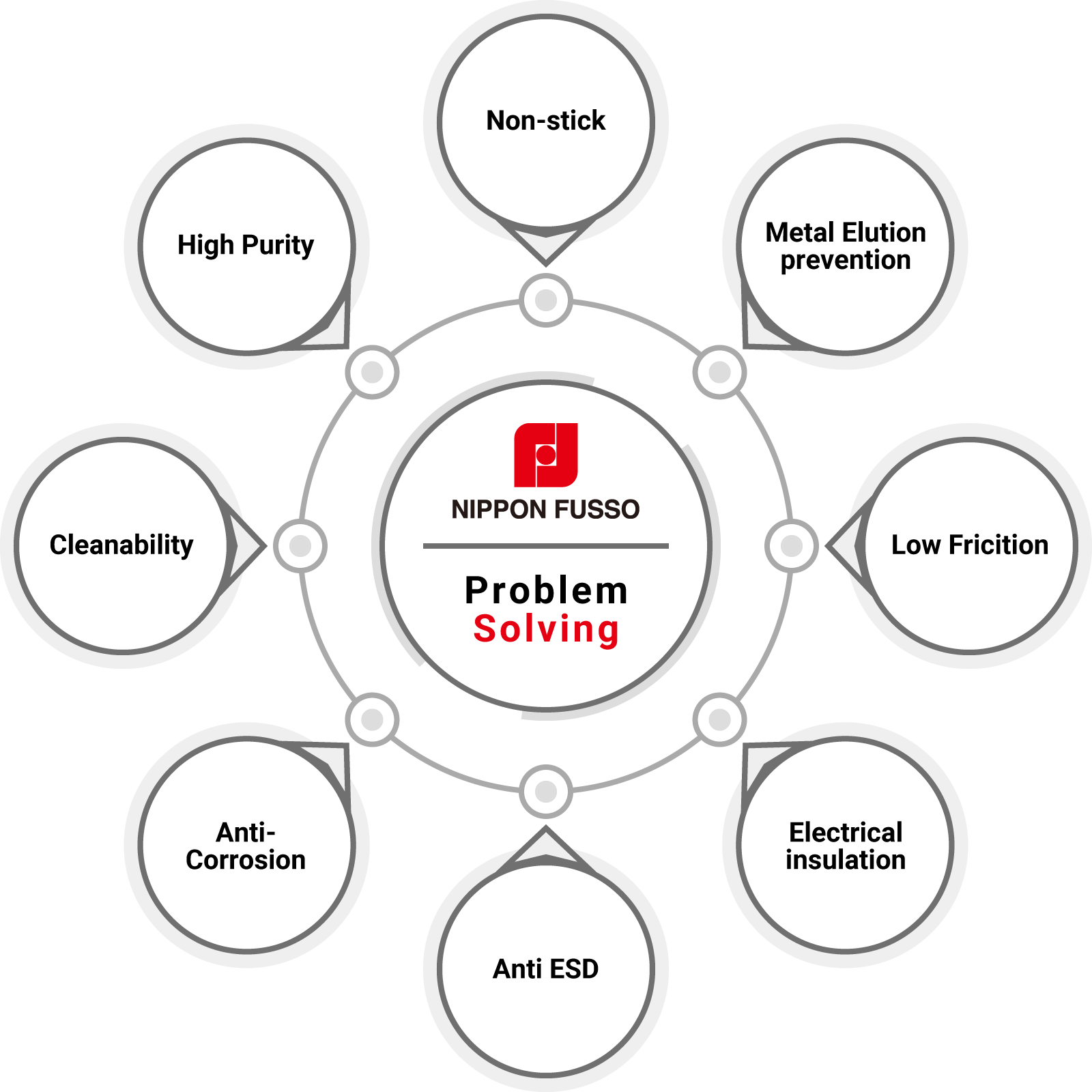

With these various excellent properties, fluoropolymer coating is being used in a various fields from household products to the space industry by adding new functions like non-stick, anti-corrosion, and low friction to their surface of substrate.

As a coating material, there are water-based, solvent-based, and powder-based materials. The fluoropolymer coating provider will select the suitable materials and fluoropolymer types based on the requirement and an actual use condition from the customers.

However, need to be noted that just coating fluoropolymer onto the surface of substrate is not good enough...

If you want to maximize the performance of fluoropolymer, understanding its properties and behavior of fluoropolymer correctly, and also reliable technology and process are essential to match the customer's expectation.

How the coating process done ?

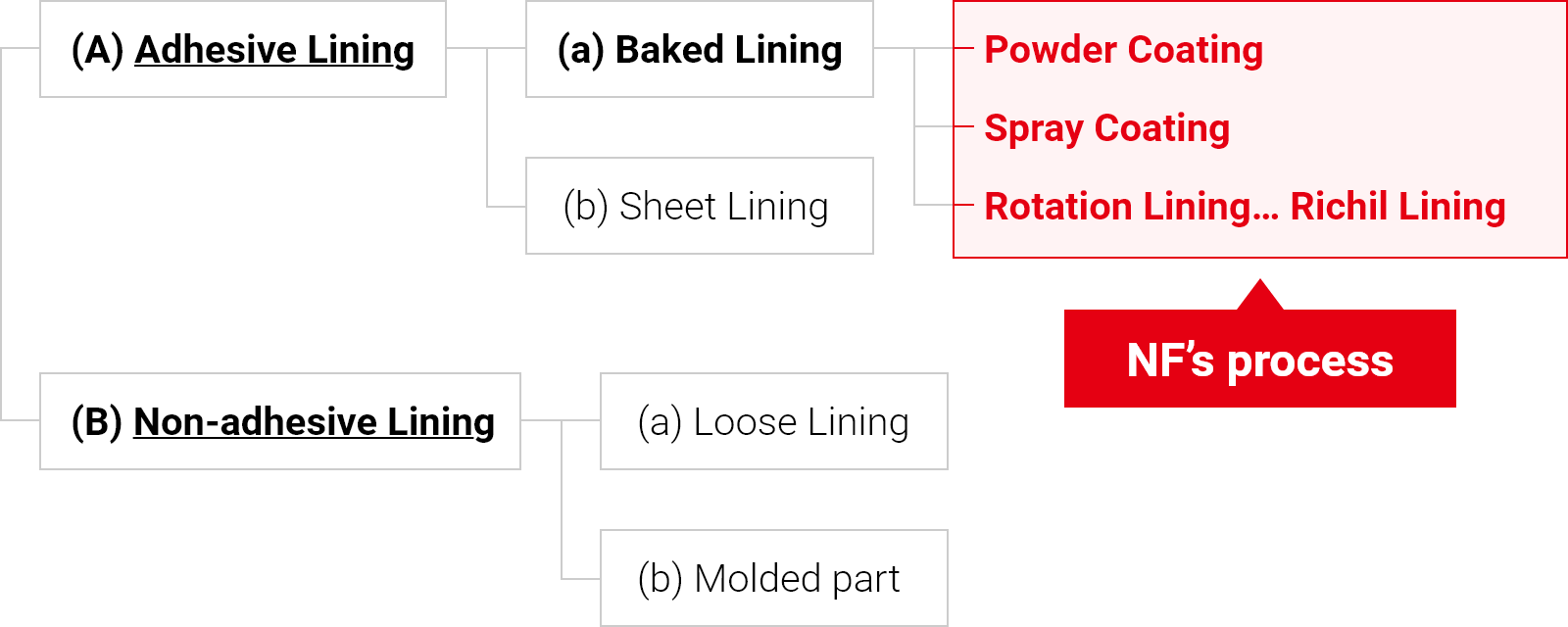

As shown below, there are several type of fluoropolymer coating methods. And NF has been applying a baking type process for over 50 years.

Hint : How to select the coating type

| Spray Coating | Rotation Lining | Loose Lining | Sheet Lining | Glass Lining | ||

|---|---|---|---|---|---|---|

| Bonding Strength between Film and Substrate |

with glue |

|||||

| Annealing during Process |

~ 400°C | ~ 400°C | N/A | N/A | ~ 900°C | |

| Processable Shape of Substrate | Very flexible. Besides long, small dia plumbing | Flexible, but only inside of tank and/or plumbing | Basically, only for cylindrical shape | The absence of complex convexity | The absence of complex convexity | |

| Use Condition |

Max Operating Temp*1 | ~ 260°C | ~ 260°C | ~ 260°C | ~ 150°C | ~ 230°C |

| Under Negative Pressure | ||||||

| Anti-Electrostatic | ||||||

| Anti-Chemical (Alkari) | ||||||

| Anti-Chemical (Acid) | ||||||

| Anti-Checamil (Solvent) | ||||||

| Other Remarks |

Bent Hole | N/A | N/A | |||

| Hardness | Soft | Soft | Soft | Soft | Hard but risk for break |

|

| On-site Process | ||||||

| Repair / Re-Lining | Only repair |

|||||

- : Usable

- : Usable, but some restriction

*1 Max operation temp will be changed by other condition

* The above chart is written based on NIPPON FUSSO's own research. Further clarification, please contact us.